Learn the critical differences between commissioning, qualification, and validation in regulated industries like pharmaceuticals, biotechnology, and medical devices. Ensure compliance with expert guidance from BioBoston Consulting.

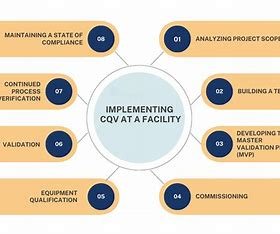

In industries such as pharmaceuticals, biotechnology, and medical devices where regulatory standards are strict, understanding the distinctions between commissioning, qualification, and validation is crucial. These three processes ensure that systems, equipment, and facilities operate safely, effectively, and in compliance with regulatory guidelines. Mastering these processes strengthens product safety, operational efficiency, and compliance throughout the product lifecycle.

What Is Commissioning, Qualification, and Validation?

- Commissioning, Qualification, and Validation (C&Q) are essential processes that ensure the facilities, systems, and equipment are fit for their intended purposes. Together, C&Q and validation ensure compliance, quality, and reliability in regulated industries. Commissioning refers to the engineering exercise that begins with the installation of equipment and systems. It is a structured approach that ensures all facilities, systems, utilities, and equipment are in place and function as per the predefined design requirements.

- Qualification goes a step further by ensuring that systems and equipment meet the necessary performance criteria to reliably operate as intended. It involves testing and documenting the functionality, reliability, and performance of the equipment or system in accordance with regulatory and user specifications.

- Validation confirms that a system or process consistently produces the desired results over time, meeting predetermined quality and safety standards. It validates whether equipment or systems are functioning properly in real-world conditions and ensures consistent output.

The Role of Commissioning in Setting Up Systems for Success

Commissioning is the foundational process in setting up equipment, systems, and facilities. It involves a thorough, documented approach to the start-up and handover to end-users. Key activities in commissioning include:

- Reviewing engineering designs

- Installing and decommissioning equipment

- Conducting risk assessments

- Ensuring alignment with qualification processes

The aim of commissioning is to ensure that all equipment and systems are safe, functional, and meet design requirements. Commissioning typically focuses on equipment and system specifications and sets the stage for the qualification process.

Qualification: Verifying System Readiness and Reliability

Once commissioning is complete, Qualification ensures that systems and equipment meet user requirements and regulatory standards. Qualification is more focused on the performance and functionality of systems in real-world conditions. It involves three primary stages of testing:

- Installation Qualification (IQ): Verifying that systems are installed as per design specifications.

- Operational Qualification (OQ): Ensuring that systems operate as expected across all intended operating conditions.

- Performance Qualification (PQ): Testing to ensure systems consistently perform according to their intended purpose under actual operating conditions.

Qualification involves establishing documented evidence that systems meet critical performance criteria and regulatory requirements. The emphasis is placed on the ability of systems to deliver product quality.

Validation: Ensuring Consistency and Compliance

Validation is the final step in the process. It ensures that systems, processes, or equipment consistently produce quality products within specified parameters. Validation activities include:

- Generating documented evidence to demonstrate that the system performs as intended

- Verifying that the system’s outputs consistently meet the established quality attributes

Upon completing the validation process, systems or equipment are ready for routine production. However, the validation state needs to be continuously monitored through Continued Process Validation (CPV), ensuring ongoing compliance and optimal system performance over time.

The Critical Differences Between Commissioning, Qualification, and Validation

| Commissioning | Qualification | Validation |

| Focuses on system and equipment installation. | Verifies that systems and equipment operate according to predefined specifications. | Ensures that systems consistently produce the desired product quality. |

| Acceptance criteria are based on equipment functionality. | Acceptance criteria are based on product quality. | Ensures the entire process produces reliable, consistent results. |

| Emphasizes engineering and design aspects. | Involves operational testing (IQ, OQ, PQ) to validate system performance. | Involves generating evidence of consistent results over time. |

BioBoston Consulting: Your Trusted Partner in CQV Processes

Mastering the distinctions between Commissioning, Qualification, and Validation is crucial for ensuring regulatory compliance and maintaining high-quality processes within regulated industries. These three critical stages play a pivotal role in ensuring safety, efficacy, and compliance in everything from equipment installation to ongoing production.

At BioBoston Consulting, we specialize in helping businesses navigate the complexities of Commissioning, Qualification, and Validation (CQV). Our comprehensive CQV services ensure that your systems and processes meet the rigorous standards set by regulatory bodies such as the FDA, European Commission (EC), and other global agencies. Whether you are in research and development, clinical trials, quality control, or manufacturing, we are here to assist with optimizing your CQV processes and ensuring compliance with industry regulations.

Partner with BioBoston Consulting to elevate your regulatory standards and streamline your operations for continuous success. Reach out to us today!